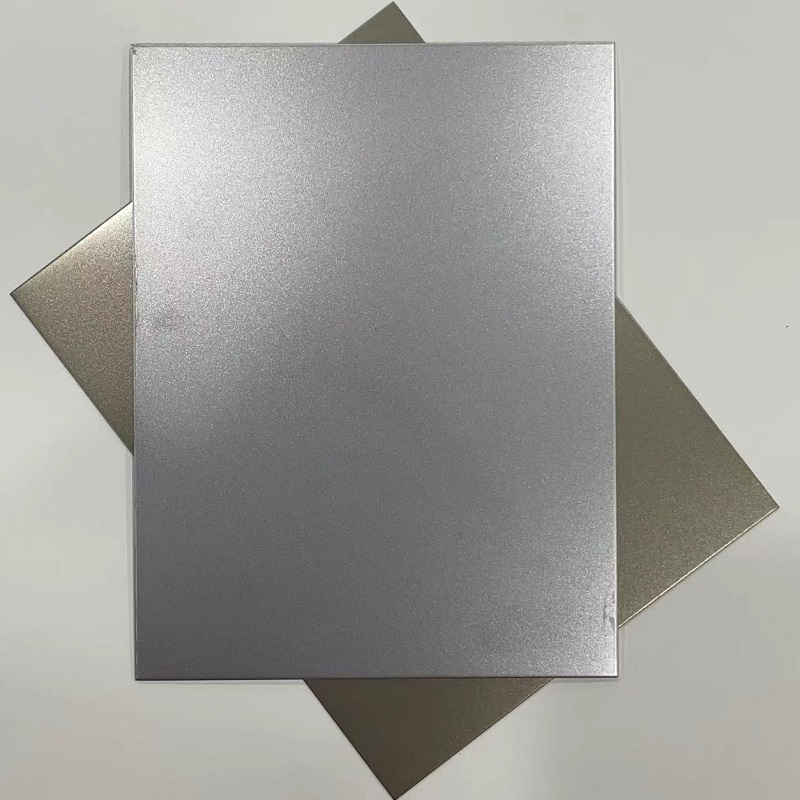

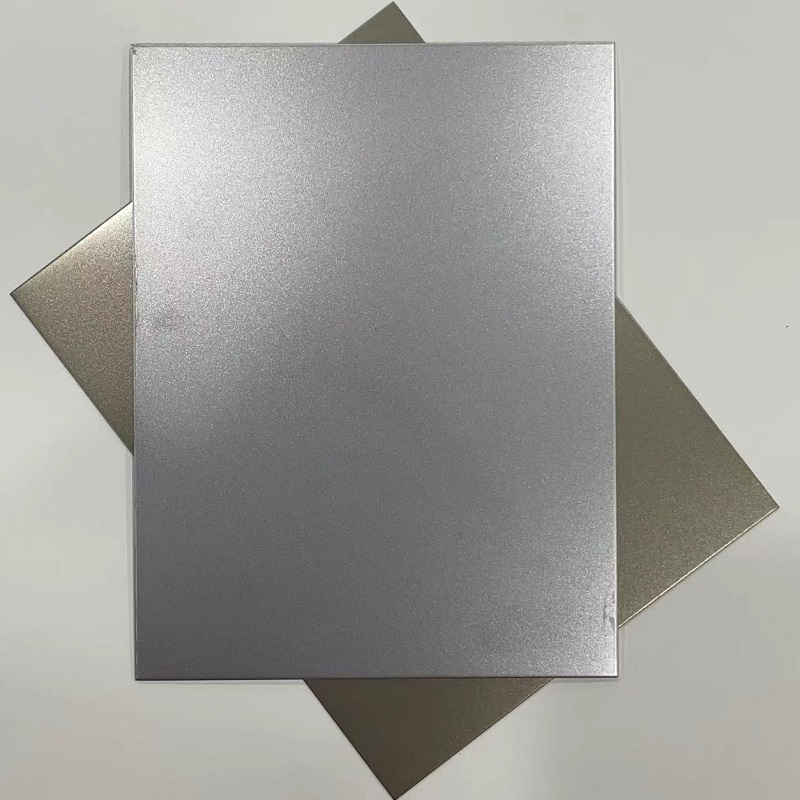

Stainless steel is renowned for its durability, corrosion resistance, and sleek aesthetic appeal. Among the various finishes applied to stainless steel surfaces, bead blasting stands out as a technique that not only enhances the material's functionality but also adds a distinctive texture.

1. Bead Blasting Process:

1.1 Abrasive Media:

Bead blasting involves propelling fine abrasive media, often small glass beads or ceramic particles, at high velocity against the surface of stainless steel. This process removes contaminants, scales, and oxides, leaving a clean and textured finish.

1.2 Controlled Pressure:

2.1 Uniform Satin Finish:

2.2 Enhanced Corrosion Resistance:

2.3 Concealed Scratches:

3. Applications of Bead Blasted Stainless Steel:

3.1 Architectural Finishes:

Bead blasted stainless steel finds widespread use in architectural applications, such as building facades, handrails, and interior design elements. Its aesthetic appeal and resistance to corrosion make it a favored choice for both indoor and outdoor installations.

3.2 Consumer Products:

Consumer products, including appliances, kitchenware, and electronic devices, often feature bead blasted stainless steel finishes. The textured surface not only adds a tactile quality but also contributes to a contemporary and refined appearance.

3.3 Automotive Components:

Certain automotive components, such as trim pieces and exhaust systems, may utilize bead blasted stainless steel finishes for both functional and aesthetic reasons. The enhanced corrosion resistance is particularly valuable in automotive applications.

4. Maintenance and Cleaning:

4.1 Routine Cleaning:

5. Customization Options:

5.1 Texture Variations:

In conclusion, bead blasted stainless steel represents a fusion of form and function. The controlled abrasion process not only enhances the material's corrosion resistance but also imparts a unique and textured finish. With applications ranging from architectural designs to consumer products, bead blasted stainless steel has secured its place as a versatile and aesthetically pleasing option in the realm of metal finishes. Its ability to combine durability, corrosion resistance, and visual appeal makes it a preferred choice for those seeking both functionality and style in stainless steel applications.

Comments

All Comments (0)